Aluminum aerospace machining. The aerospace and defense industry demands the highest standards of precision, performance, and reliability. In short, manufacturing parts for the aerospace sector doesn’t allow for human errors. Aluminum aerospace machining at Roberson Machine Company is the ideal scenario, providing the perfect blend of strength, lightness, and corrosion resistance essential for your parts.

When you’re in need of aerospace parts, as well as finding the right machining solution that will save you time and money, call Roberson Machine Company right away at 573-646-3996 or contact us online for a quote. Our team has over 20 years of experience machining aluminum aerospace parts for industry-leading companies across the country.

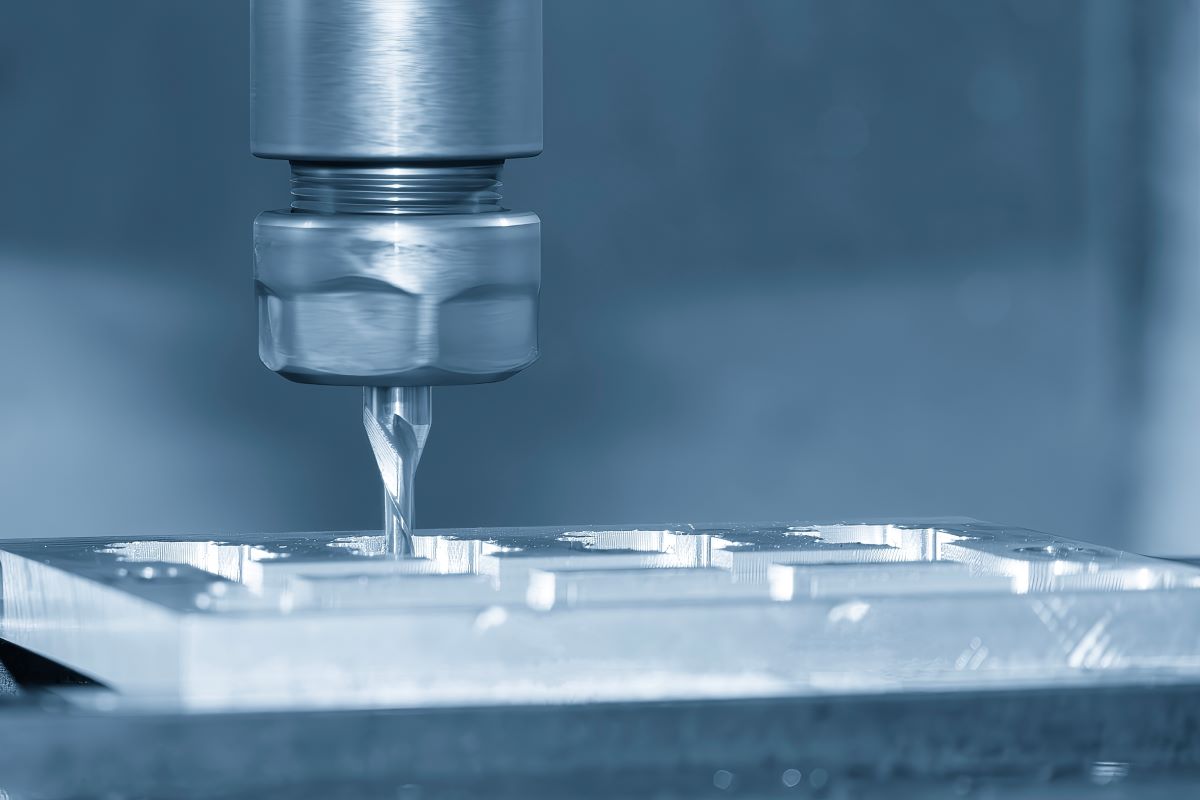

CNC machining is truly at the forefront of aluminum aerospace machining, offering unrivaled precision and repeatability. Our team of experts utilizes higher cutting speeds and feed rates, achieving finer finishes and tighter tolerances, crucial for aerospace parts. Our machine shop also gives us the capacity to manufacture aluminum aerospace components using 5-axis machining and even 3D printing services.

Aluminum Aerospace Machining: The Unique Benefits of CNC Machining at Roberson Machine Company

Our unparalleled CNC machining solutions allow us to manufacture your aerospace parts with tolerances as low as a few microns. This absolute level of precision is necessary for the aerospace and defense sector – where the smallest error could seriously affect the finished product, as well as someone’s safety.

Our aluminum aerospace machining solutions include automation and robotic machine tending, allowing us to manufacture “lights out,” with the capabilities of finishing large production runs quickly and accurately, reducing lead times, and passing along the savings to you. Also, we have the ability to manufacture parts with complex shapes and intricate designs. Our CNC machines move along multiple axes simultaneously, allowing us to create precise angles and complex geometries.

Why Aluminum is Crucial for Aerospace Machining

Roberson Machine Company is a leading manufacturer of aluminum aerospace parts. Give us a call today at 573-646-3996 or reach out to us online to get a quote on our aluminum aerospace machining.

The following are reasons we rely on aluminum for your components:

Aluminum is Lightweight & Strong

This is one of the primary reasons aluminum is favored for your aerospace parts – its exceptional strength-to-weight ratio. Your parts need to be as light as possible, yet strong enough to withstand substantial stresses. Aluminum delivers on both counts, making it an ideal material for everything from fuselages to wing structures.

Thermal Conductivity of Aluminum

Aluminum’s excellent thermal conductivity assists in heat dissipation, which is vital for managing the thermal loads of air travel. This ensures that your aerospace parts can operate efficiently and safely under various temperature conditions.

Aluminum’s Corrosion Resistance

Aluminum naturally forms a protective oxide layer that makes it highly resistant to corrosion. This is particularly valuable in aerospace and defense, where parts are exposed to harsh environments and need to maintain their integrity over long periods of time.

Aluminum is Highly Versatile & Recyclable

Being easy to machine – thanks in large part to being dimensionally stable with lower density and tensile strength – aluminum can be used for CNC machined parts in various shapes, sizes, and designs. Additionally, an estimated 75 percent of all aluminum manufactured is still in use today. This flexibility and recyclability is important to the aerospace and defense sector, allowing for more precision and refined components.

Call the aluminum aerospace machining team at Roberson Machine Company as soon as possible at 573-646-3996 or contact us online to get a free quote for your company’s next aluminum aerospace part project.

Applications of Aluminum Aerospace Machining

Parts for the aerospace industry have many uses for aluminum materials and CNC machining at Roberson Machine Company. The following are some of the most common applications:

- Electrical Connectors: CNC machining aids the production of an aircraft’s vital electrical system. Manufacturing parts for the electrical system is frequently dependent on weight, strength, and space constraints – making aluminum the ideal material choice.

- Engine Parts: Engine components require materials that can withstand high temperatures and stresses. Aluminum’s strength and thermal conductivity make it an optimal choice for various engine parts, contributing to efficient engine performance and longevity.

- Structural Components: Aluminum is used extensively in the construction of aircraft fuselages, wings, and other structural components. Its strength and lightweight nature help reduce the overall weight of the aircraft, boosting fuel efficiency and overall performance.

- Valve Components: These tiny parts have widespread applications in the aerospace industry and our CNC machined valve parts ensure accuracy and efficiency in aircraft operations.

- Avionics & Control Systems: Precision-machined aluminum parts are integral to the avionics and control systems of modern aircraft. These parts must meet stringent standards to ensure reliable operation and safety.

Connect With a Leader in Aluminum Aerospace Machining Right Away at Roberson Machine Company

Aluminum aerospace machining is the bedrock of modern aviation, providing the essential characteristics and properties necessary for your high-performance parts. Our advanced aluminum machining techniques ensure the production of precise, reliable, and cost-effective aerospace components.

For your company, leveraging the capabilities of aluminum machining at Roberson Machine Company is crucial for staying ahead of the competition in the dynamic aerospace industry. Call us right away to do just that at 573-646-3996 or contact us online for a free quote.