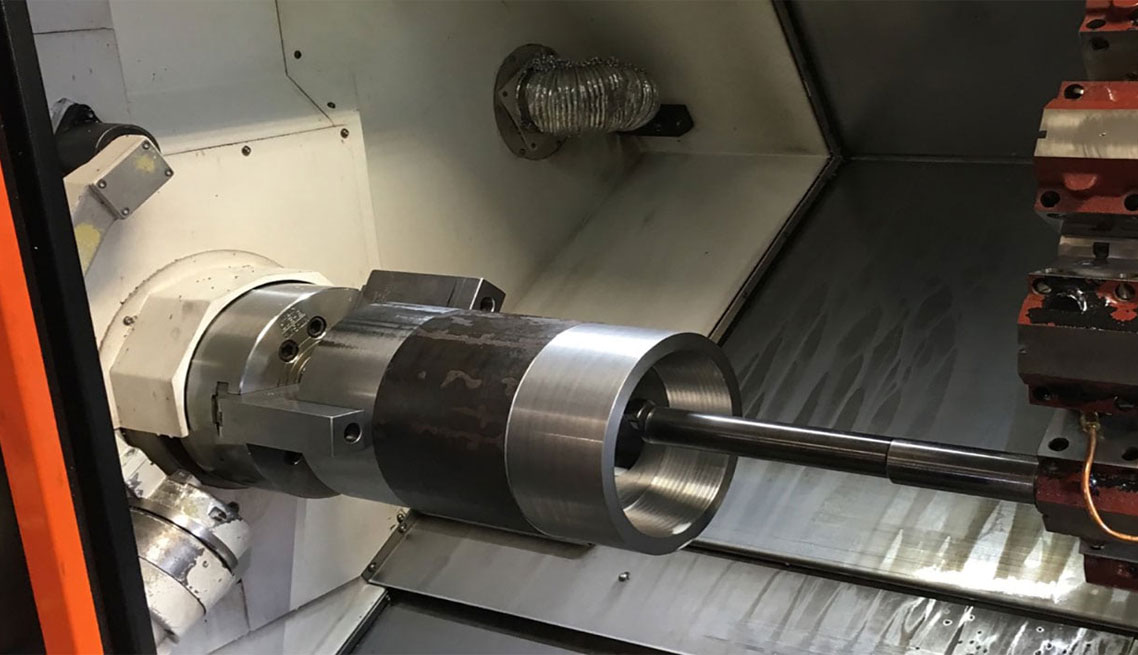

Production CNC Turning. CNC (Computer Numerical Control) Turning involves rotating and cutting a workpiece during production, while the machine remains stationary. The machine, a lathe, spins the material on a vertical or horizontal axis. A basic CNC lathe used in production operates on two axes and the tool is located in a fixed position. More advanced CNC lathes have 3-axis, 4-axis, and 5-axis capabilities. The rotating action of the part is called “turning,” hence many CNC lathes are referred to as production CNC turning machines.

Get an instant quote from Roberson Machine Company on your next CNC turning project, contact us, or give us a call today at 844-706-7710.

Benefits of Using Production CNC Turning

Much like CNC mills, CNC lathes can be utilized for extreme accuracy. In a single production run, lathes can easily turn out thousands of components that are each identical. Our customers’ CNC turning needs vary, so we strive to provide the best service within a moment’s notice. Thanks to our skilled staff and production CNC turning capabilities, where there is minimal opportunity for human error, we are able to maintain impeccable results, even when a demanding specification is required.

The Top 5 Benefits of Using Production CNC Turning Are:

- Accuracy — By using CAD and CAM software, a CNC turning machine can perform the most rigorous of cuts or measurements perfectly. Using our CNC turning system, our expert machinists can guarantee precise accuracy in prototyping or entire production runs.

- Repeatability — Our CNC turning system can produce large batches of accurate products. Each and every time. We maximize our production CNC turning output and reduce waste, and pass along the savings to you.

- Flexibility — Roberson Machine Company specializes in operating multiple CNC turning machines or lathes at once. We frequently have customers that need varying sized materials. Our operators can quickly alter sizes via our CAD and CAM programmed G- and M-code, allowing us to provide you with a large number of unique parts.

- Speed — Due to an extremely low risk of error, the Roberson CNC turning machines complete production faster without affecting the quality of the finished product.

- Safety — We have over 20 years of production experience operating CNC turning machines. We adhere to strict certifications and regulations, and we know what to be on the lookout for. All of our CNC turning machines are enclosed with protective devices, and our specialists all wear the best protective gear. Our CNC turning machines are automated, meaning that while our skilled machinists are present and have programmed the CNC specs, they are not constantly hands-on “on the machine.”

Custom Sourced Materials Available for Production CNC Turning Capabilities

We use only the best available source materials for our production CNC turning customers. If you do not see what you are looking for, please contact us or give us a call at 844-706-7710 and we’ll be sure to get what you need. Our scope of materials available for production CNC turning includes:

ALUMINUMS

A wide range of aluminums including: 6061, 7075, 7050

STEELS & ALLOYS

A wide range of steels and alloys including: A-36, C1018, 4140, 1045, A2, D2, S7

STAINLESS STEEL

A wide range of stainless steels including: 303, 304, 316, 321, 420SS, 416, 440

OTHERS

A wide range of plastics including: Delrin, Nylon, PEEK, HDPE and Glass Filled Nylon. Other metals including: Bronze and Brass

Contact Your Production CNC Turning Experts | Roberson Machine Company

Our production CNC turning machines and lathes allow us to produce the parts to meet your needs and specifications, offering precision, scalability, custom finishes, and vast material selection — all with rapid turnaround times. We have the capacity to handle a variety of your CNC turning and lathe production plans from prototyping to short, medium, or long production runs.

For assistance with your next production CNC turning project, or to see our newest lathe, give us a call today at 844-706-7710 or reach out to us for a free quote.