If you deal with machining parts, even at a passersby level, you have seen burrs on parts at least once. We see them at Roberson Machine Company constantly. Burrs, which are defined as rough edges or ridges left on an object, especially of metal, by the action of a tool or machine, can affect the quality of the parts you make and sell, and render their surface unsmooth. Conversely, deburring is the removal of such imperfections, utilizing manual tools, like knives and files, or electric ones such as grinders or brushes.

Roberson Machine Company is a leading contract manufacturing company specializing in CNC machining services. Call us today at 573-646-3996 or contact us online.

We see thousands of burrs relatively routinely, despite using high-quality metal materials, including:

- Aluminums:

- Stainless steel:

What Causes Burrs When Machining?

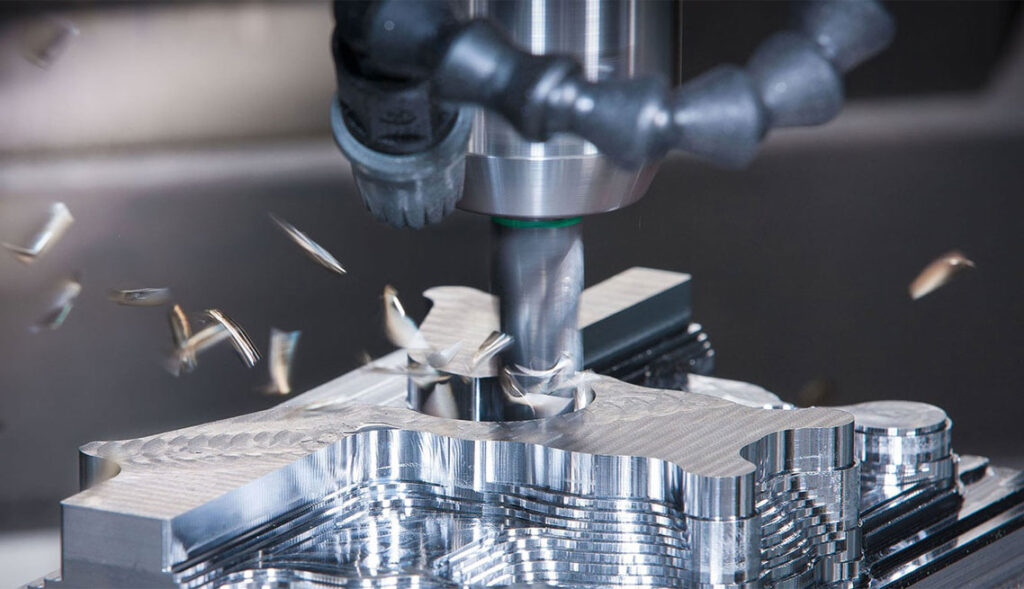

Despite being proactive and working hard to produce a flawless, smooth part, our Roberson Machine Company CNC machinists see these small blemishes, tiny specks of imperfections. Burrs are an unfortunate, yet fairly common occurrence in the following machining and cutting processes:

- CNC Turning

- CNC Milling

- Drilling

- Engraving

- Laser cutting

- Plasma cutting

- Blanking

- Shearing

An element that can contribute to burrs is the thickness and grade of the material we are working on. If our machinists are working with a quality material that’s easy to cut, our post-processing should be non-existent. This is obviously what we prefer. However, burrs can occur in our machining processes in the following ways:

- Rollover Burrs

- Breakout (Cutoff) Burrs

- Poisson Burrs

Our machinists occasionally find tiny bits of curled metals on the surface of their parts projecting upwards. These are the most common types of burrs.

Less common, but our machinists still see them — tiny bits that look like they’re breaking out of the machined part. They have an upswell shape, which explains why they look like they want to break out.

Our specialists see these as tiny bits at the end of their machined part extending sideways.

What Issues Can Burrs Cause While Machining?

Burrs can impact a part’s functionality, longevity, safety, and effectiveness. Burrs can cause the following:

- Decreased resistance to fractures

- Fastener and material problems

- Improper seating of fasteners, causing damage to the fastener of assembly

- Material failure due to cracks

- Increased risk of corrosion

- Concentrated electrical charge, risk of static discharge

- Unwelcome friction and heat

- Issues with lubrication due to increased wear at interfaces

- Shortened ability to withstand stress cycles

- Unsafe handling

What Deburring Techniques Do You Use?

Roberson Machine Company uses a variety of techniques to make sure we provide high-quality, burr-free finishes on all of our parts, including:

- Manual Deburring

- Electrochemical Deburring

- Thermal Energy Method

- Mechanical Deburring

This is our most common method due to its customizability, flexibility, and cost savings we can pass along to our customers. We can immediately inspect the results, right out of the hands of our specialists.

Electrochemical deburring is useful for difficult materials and hard-to-reach spots. Using a combination of electricity and a salt or glycol solution, our team can dissolve the burrs without impacting surrounding material.

The thermal energy method (TEM) is also ideal for hard-to-reach burrs, and can target multiple surfaces simultaneously. This process requires an explosive gas mixture to essentially burn off burrs.

Our machinists remove burrs mechanically by either grinding them or rolling the edge into itself. This process provides high-quality finishes in a fraction of the time it takes to deburr by hand.

What is Deburring? | Roberson Machine Company

Looking for a single-source manufacturing company that can bring your parts production to life? Look no further than Roberson Machine Company. In addition to offering unrivaled CNC machining services, along with owning our own land and facilities in a convenient, central location for fast delivery times with access to major markets, we ensure your products are free from burrs and look as professionally machined as possible.

Call us today at 573-646-3996 or contact us online.