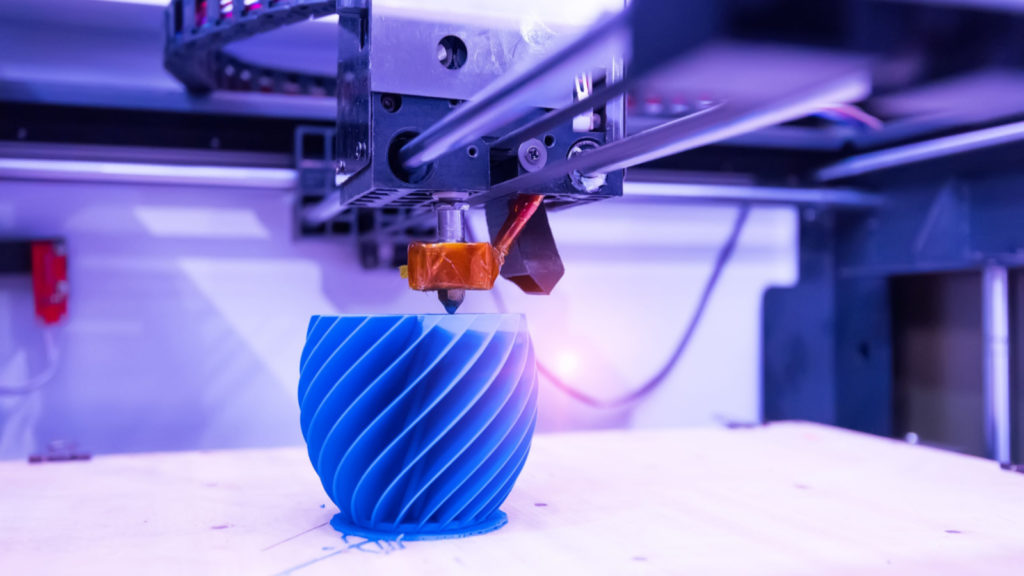

3D printing, also known as additive manufacturing, is becoming popular with manufacturers. Enough so, that your friends at Roberson Machine Company recently purchased a machine.

Our new machine makes us a more well-rounded and adaptive manufacturer, now having the ability to use cutting-edge manufacturing technology to create 3D-printed parts with complex geometries and excellent surface detail. We’d love to discuss your 3D printing plans.

Our expert staff will work with you to unlock your project’s potential. Give us a call at 573-646-3996 or contact us online.

What Are the Advantages of 3D Printing?

Roberson Machine Company realizes the demand of 3D printing is growing due to the revolutionary benefits it can provide, including:

- Flexible Design

- Rapid Prototyping

- Print on Demand

- Strong and Lightweight Parts

- Fast Design and Production

- Minimizing Waste

- Cost Effective

- Advancing Technologies

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes tend to have design restrictions that no longer apply with the use of 3D printing.

3D printing can manufacture parts within hours, which speeds up the prototyping process. This allows for each stage to be completed faster. When compared to machining prototypes, 3D printing is cheaper and quicker at creating parts as the part can be completed in hours, allowing each design modification to be completed at a much more efficient rate.

Print on demand is another advantage, in that it doesn’t need a lot of space to stock inventory. This saves physical space and costs, as there is no need to print in bulk unless required. The 3D design files are all stored virtually, as STL(Standard Triangle Language) files.

In 3D printing designs, an STL file uses a series of linked triangles, known as tessellation, to represent the surfaces of a solid model. All modern CAD (Computer Aided Design) software allows you to export their native file format into STL. The 3D model is converted into machine language, known as G-code, through a process called slicing, and is ready to print.

The main 3D printing material used is plastic, although we can also use our high-quality metals. Our plastics offer advantages as they are obviously lighter than their metal counterparts. This is particularly important for our customers in the automotive and aerospace industries, where lighter weights can deliver greater fuel efficiencies. Also, parts can be created from tailored materials to provide specific properties such as heat resistance, higher strength, or water repellency.

Depending on a part’s design and complexity, we can print parts within hours, which is much faster than molded or machined parts. Not only are we saving manufacturing time, our specialists are quick at creating STL and CAD files that are ready to be printed in a matter of minutes. If you need various adaptations on the fly, we can help. Give us a call at 573-646-3996 or contact us online.

The production of parts in 3D printing only requires the materials needed for the part itself, with little or no waste compared to alternative methods which are cut from large chunks of nonrecyclable materials. Not only does the 3D printing process save on resources, it also reduces the cost of materials.

As a single-step manufacturing process, done by a single-source manufacturer like Roberson Machine Company, 3D printing, as well as any assortment of CNC machining you need, saves time and associated costs with using different machines and different companies. Like our CNC machines, 3D printers can be set up and automated, meaning our machinists can run multiple jobs simultaneously.

3D printing is being used in the medical industry to help save lives by printing organs for the human body such as lives, kidneys, and hearts. Further advances and uses are being developed on a daily basis, and Roberson Machine Company looks forward to providing some of the biggest advances from using the technology.

What Are the Advantages of 3D Printing? | Roberson Machine Company

We provide the best in on-demand manufacturing. Whatever the parts needed and whatever the size of the production run, Roberson Machine Company is ready to make your project possible.

Give us a call at 573-646-3996 or contact us online.