Anodizing is a key step in manufacturing aluminum CNC machined parts. The process converts a metal surface, normally aluminum, into a decorative, durable, corrosion resistant, anodic oxide finish. In short, anodizing is the finish of choice at Roberson Machine Company.

Roberson Machine Company, a leader in the CNC machining and contract manufacturing industries, recently acquired state-of-the-art coating and anodizing equipment and is excited to offer its customers these services. Call us today at 573-646-3996 or contact us online.

Anodizing ensures a part can resist corrosion and wear and tear from prolonged use, and it retains its cosmetic appearance under any conditions or exposure to various elements. Roberson Machine Company has the equipment and capabilities to utilize any of the three common types of anodizing, depending upon the customer’s need:

We currently offer both clear and black anodized coatings. More colors are available on request. Give us a call at 573-646-3996 or contact us to talk about your anodizing project.

Aluminum anodizing is a popular choice for a wide range of industries including:

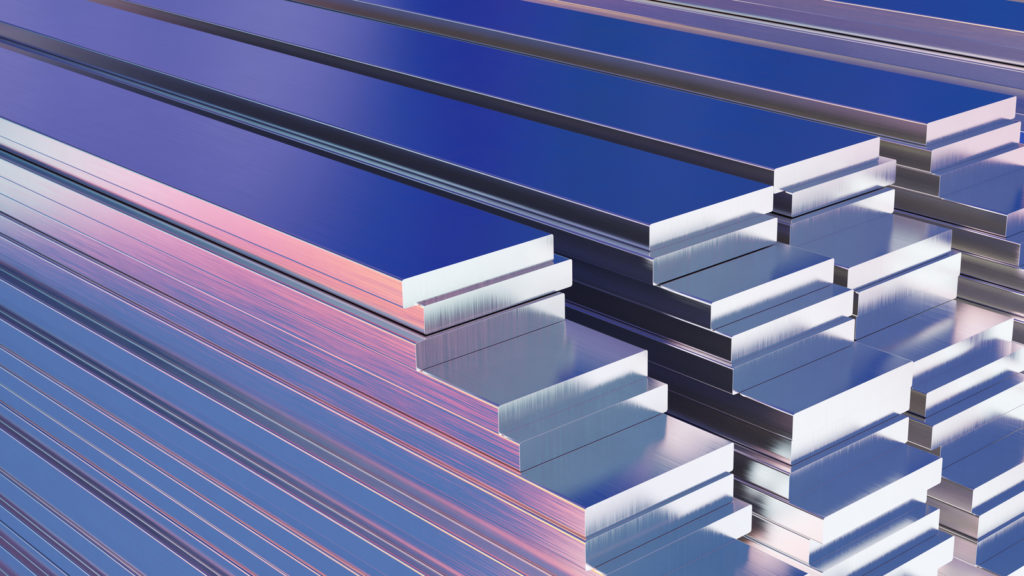

The types of high-grade aluminum we use in our anodizing process include:

What Are the Benefits of Anodizing?

Anodizing increases the lifespan and durability of aluminum. The process has made aluminum one of the most respected and widely used materials today in the production of thousands of consumer, commercial, and industrial products. Anodized aluminum protects satellites from the harsh environment of space and is used in one of the world’s tallest buildings — the Willis Tower in Chicago. It is also considered environmentally safe, producing few, if any, harmful effects on land, air, or water. Some other benefits of aluminum anodizing are:

- Durability — Most anodize products have an extremely long lifespan and offer significant economic benefits through maintenance and operating savings.

- Ease of Maintenance — Scars and wear from fabrication, handling, installation, frequent surface dirt cleaning and usage are virtually nonexistent. Rinsing or mild soap and water cleaning usually will restore an anodized surface to its original appearance.

- Cost — A lower initial finishing cost combines with lower maintenance costs for greater long-term value.

- Color Stability — Exterior anodic coatings provide good stability to ultraviolet rays, do not chip or peel, and are easily repeatable.

- Aesthetics — Anodizing offers a large increasing number of gloss and color alternatives and minimizes or eliminates color variations. Unlike other finishes, anodizing allows the aluminum to maintain its metallic appearance.

- Health and Safety — Anodizing is a safe process that is not harmful to health. An anodized finish is chemically stable, will not decompose, is non-toxic, and is heat-resistant to the melting point of aluminum (1,221 degrees Fahrenheit). Since the anodizing process is a reinforcement of a naturally occurring oxide process, it is non-hazardous and produces no harmful or dangerous byproducts.

What is Anodizing? | Roberson Machine Company

The addition of onsite anodizing is another in a long list of Roberson Machine Company’s value-added services. We provide these services as a one-stop shop, meaning that there is no need to contract with multiple firms for your next project. We do it all. On our own land. In our own shop. We are ideally situated in a central location, for fast delivery times and access to major markets.

Call us now at 573-646-3996 or contact us online to get started on your next anodizing project.