Very few substances can match the versatility and durability of aluminum. In the aerospace and defense industry, choosing the right material for your parts – as well as the manufacturer producing those parts – is crucial. The aluminum aerospace machining experts at Roberson Machine Company are here to help.

Aluminum is highly machinable and relatively inexpensive, making it ideal for CNC machining. Its flexibility and impressive strength-to-weight ratio make it perfect for exterior applications on all forms of transportation, but particularly within the aerospace and defense industry, as a greater emphasis has been placed on fuel efficiency and lightweighting.

Not all aluminum alloys are created equal though, especially for aerospace applications. If you wondering what the best type of aluminum alloy is for your aerospace parts, call Roberson Machine Company right away at 573-646-3996 or contact us online for a quote. Here, we’ll explore the best types of aluminum for your parts and why they’re preferred in this industry that relies so heavily on safe, high-quality materials for components.

Why Choose Aluminum Alloys for Aerospace Parts at Roberson Machine Company?

The aerospace and defense sector demands materials that withstand extreme conditions, yet maintain their integrity and performance. Our aluminum alloys offer the perfect combination of strength, light weight, and corrosion resistance to produce aerospace parts that contribute to the overall safety and reliability of an aircraft.

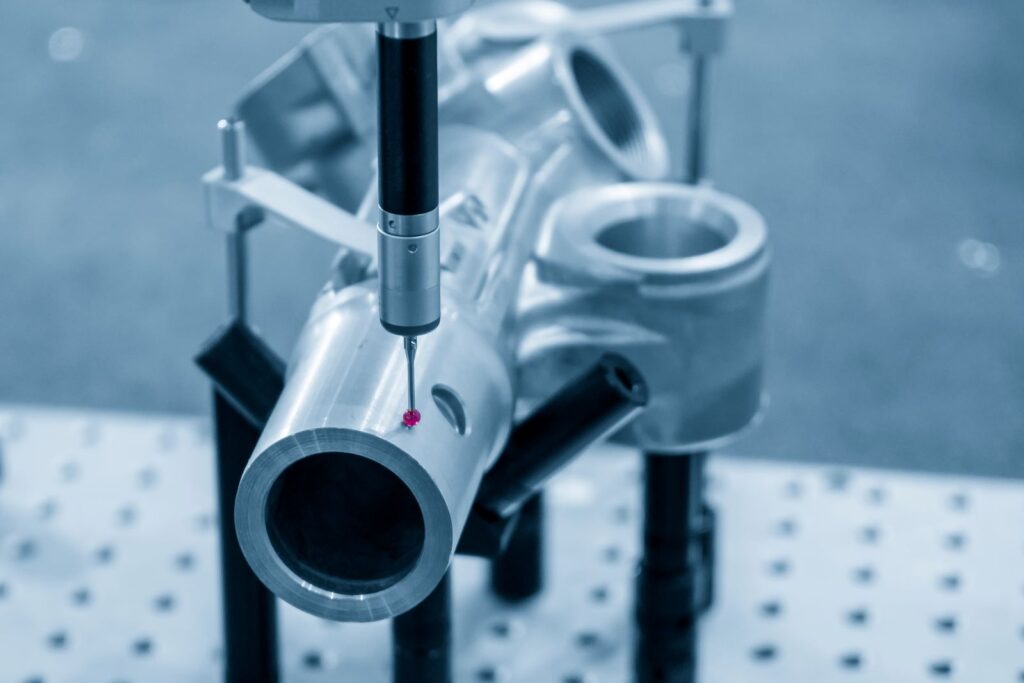

At Roberson Machine Company, we specialize in machining top-quality aluminum aerospace parts to meet the exacting standards and regulations of your high-stakes industry. We have over 20 years of experience manufacturing aerospace components with a variety of unparalleled machining solutions, including:

- CNC Milling, including Multi Axis and 5 Axis Machining

- CNC Turning

- Wire EDM

What Are the Best Types of Aluminum For Your Aerospace Parts?

By working together to choose the appropriate aluminum alloy for your aerospace parts, we can ensure your components perform reliably at a high level in even the most demanding environments. Whether your project calls for high strength, superb resistance to corrosion, or superior thermal conductivity, there’s both an alloy and a machining solution at Roberson Machine Company that precisely fits your needs.

We typically use the following types of aluminum for industry-leading customers needing aerospace parts:

Aluminum 2024

With its high tensile strength and fatigue resistance, aluminum 2024 is ideal for aerospace and defense applications where durability is crucial. This type of aluminum alloy is typically used in aircraft structures like wings and fuselage components.

Aluminum 7075

Aluminum 7075 is one of the strongest aluminum alloys available and it has excellent resistance to stress corrosion cracking. It is used in high-stress structural components such as aircraft wings, fittings, shafts and gears, and other critical parts. Aluminum 7075’s exceptional strength makes it a favorite with components of missiles and in military aircraft.

The experts at Roberson Machine Company can go over the pros and cons of each type of aluminum for your particular aerospace parts. Give us a call at 573-646-3996 or reach out to us online to get a free quote on your project.

Aluminum 6061

Probably the most popular aluminum alloys, as well as one of the most versatile, aluminum 6061 offers a relatively good balance of strength and corrosion resistance. Tempered to its 6061-T6 form, it has the approximate strength of structural steel. Its machinability and weldability make it suitable for aircraft fittings, hydraulic pistons, and structural components on the wings and fuselage.

Aluminum 7050

Similar to 7075, aluminum 7050 is heat-treatable, strong, and has excellent resistance to corrosion. The alloy is often used in 3-6 inch sections due to it being able to hold its strength and is used in military aircraft fuselage frames, bulkheads, and other critical structures.

Aluminum 6063

Aluminum 6063 is known for its exceptional finish and is often anodized for enhanced corrosion resistance and to improve its aesthetics. Sometimes referred to as an architectural alloy because of its formability, it is used in the aerospace and defense sector for complex shapes and profiles, like extruded sections in aircraft fuselages or other detail work.

Aluminum 5052

Aluminum 5052 offers superior resistance to corrosion and is highly machinable/weldable. The strongest among non-heat-treatable alloys, it has high ductility and is commonly used for fuel tanks and other aircraft components.

Reach Out to a Leader to Learn the Best Types of Aluminum for Your Aerospace Parts | Roberson Machine Company

Choosing the right type of aluminum for your aerospace parts is critical to ensuring safety, performance, and longevity. Alloys like 2024, 7075, 6061, 7050, 6063, and 5052 each provide unique properties that make them particularly suitable for specific applications within your sector. Our specialists can help find exactly the right one for you.

To learn more or to get a quote, call us as soon as possible at 573-646-3996 or contact us online.