Wire EDM (Electrical Discharge Machining) at Roberson Machine Company is more than a machining technique, it’s a gateway to unprecedented precision, versatility, and efficiency. With fewer moving parts than our CNC machines – combined with the ability to produce more types of shapes and paths than most CNC processes – our wire EDM services provide an optimal option for your company’s current and future needs.

Call us right away at 573-646-3996 or contact us online for a free quote and to find out more about wire EDM.

What is Wire EDM?

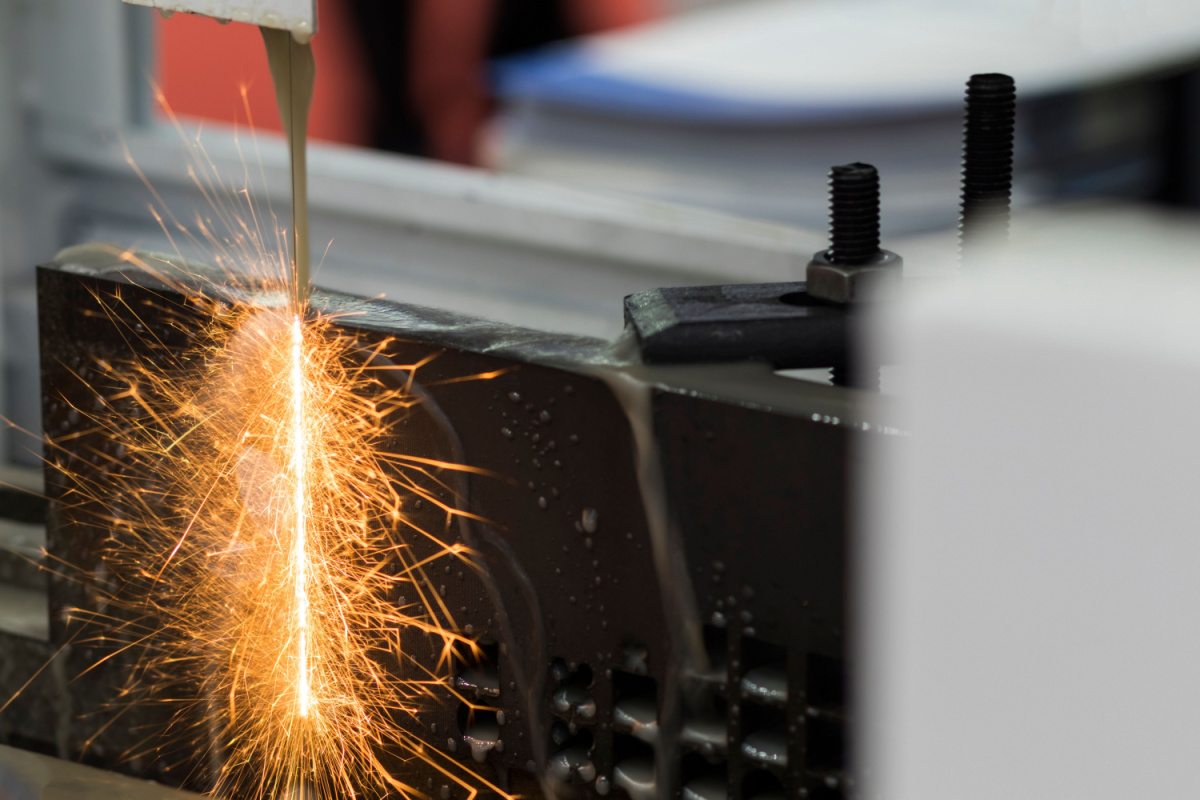

Wire EDM is a cutting-edge machining technique that uses electrical discharges to shape and refine materials, most commonly metals. It uses a small wire, with diameters measuring between 0.05 and 3.0 millimeters depending on the specifications of your company’s project, drawn across two pulleys close to the workpiece to make “cuts.” The cutting path of the wire, held in place by an upper and lower guide, can be programmed via our CNC machining technology to produce your desired shape.

Sparking rapidly creates a thermoelectric flow that pulls molecules away from the workpiece. Dielectric fluid is used to enhance the sparking and remove material.

To get started on your next wire EDM project, call Roberson Machine Company now at 573-646-3996 or contact us online for your free quote.

What are the Benefits of Wire EDM at Roberson Machine Company?

Our wire EDM machines often work faster with less downtime and less “hands-on” input from our machinists – saving your company time and money. Our advantages include:

- Absolute Precision

- Versatile Material Compatibility

- Automation and Accuracy

- Burr-Free Cuts

- Create Intricate and Complex Shapes

- Circular

- Conical

- Spherical

- Polygonal

- Orbital

- Helical

- Vertical

- Indexing

- L-spin

- Minimal Tool Wear

- Cost-Effective for Complex Parts

When it comes to precision, wire EDM is in the upper echelon. The method is capable of achieving accuracy down to the submicron level. This level of precision is essential in industries like medical and aerospace/defense, where even the smallest deviation can lead to catastrophic consequences.

Wire EDM is compatible with a wide range of materials, from metals like aluminum, brass, and steel to conductive hard plastics. This versatility makes it a valuable tool in various sectors, including automotive, medical, and aerospace.

Wire EDM can be automated in our shop, allowing for long, unattended production runs. The Roberson Machine Company CNC technology used in wire EDM ensures consistent precision, even during extended, “lights-out” operations.

The wire EDM process produces burr-free cuts, particularly important in industries where sharp edges are problematic. The absence of burrs minimizes the need for our value added services, reducing production time and costs.

Wire EDM excels at creating intricate and complex shapes. The method allows for the creation of components with tight tolerances, as well as shapes and paths that would be challenging or impossible to attain with conventional techniques. Some of these shapes and paths include:

In conventional machining, tool wear is prevalent. As cutting tools rub against materials, especially heavy metals, they gradually wear down, requiring frequent replacement and maintenance. However, utilizing our wire EDM service, there are no physical tools involved, eliminating tool wear.

While our wire EDM services may have a higher initial cost compared to some of our traditional machining methods, it becomes particularly cost-effective for intricate parts that would otherwise require multiple setups and tooling changes using conventional machining.

Reach Out to Discover the Benefits of Wire EDM | Roberson Machine Company

Offering industry-leading wire EDM and CNC services, Roberson Machine Company is truly your one-stop shop for your company’s manufacturing needs. We produce parts to meet your specifications, no matter if it’s for prototyping or for small or large production runs.

Call us today at 573-646-3996 or contact us online for a free quote.