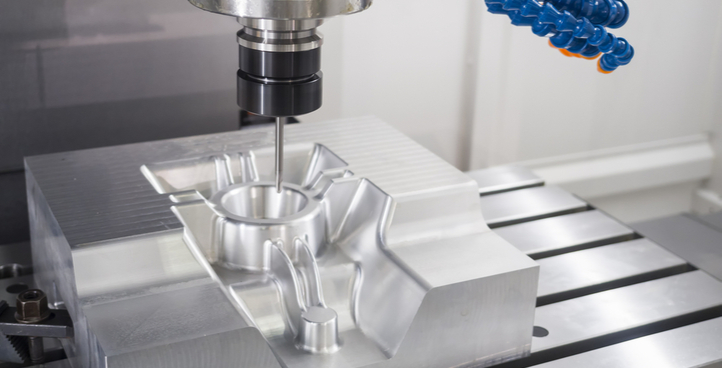

In order to see if CNC milling is right for your product or application, it’s important to know the different parts of the CNC milling machine and how they all work together to drill, cut, and shape your product into its intended end-shape.

Roberson Machine Company specializes in CNC milling in Missouri, which is an excellent solution for aerospace, medical, energy, and defense businesses across the country. Our technicians have produced precise, high-quality CNC-milled products for over two decades, and have the capabilities and experience required to exceed your CNC milling service needs.

For questions about any of the CNC mill parts below, do not hesitate to reach out to us to learn more. Contact our team at 573-646-3996 or request a quote today for more information on our Missouri CNC milling services.

Frame

The base that supports the machine and provides rigidity to resist cutting forces.. A column vertically connects the base to other components of the machine. It is heavy casting with inner spaces used to house the driving motor. It also holds the turret. provides

Saddle

Allows the workpiece to travel on the y-axis of the table. It is connected to the knee, which holds and controls the feed mechanism of the machine. It also provides z-axis vertical motion, while the cutter remains above the workpiece.

Table

The table sits on the top of the saddle and has a t-shaped slot on the surface where you can place the workpiece and secure it with a vice. It can also be directly clamped on the table, which allows the workpiece to travel on the x-axis of the table. In milling operation, the table is moved by the motor which gets signals from the program codes used in computer numerical control.

Spindle

The spindle is the rotating tool holder that acts as the heart of any milling machine. It is a large tube located on the upper part of the column that receives power from the head and transmits it to the arbor, which is an extension that mounts and rotates the cutting tool at different RPMs to cut away pieces.

CNC Controller

If the spindle is the heart, then the controller is the brain of the CNC milling process. It contains the electronics that executes the code given as the input and drive the axis motors to move along the axes. CNC Controllers are responsible for accepting G-Code and manual inputs from the CNC Control Panel and converting that into the proper signals to the motor of the machine to move in along the different axes.

Axes

The directions the machine moves, which can be programmed via g-code and manual jogging from the CNC controller. It can be along anywhere from one to six axes depending on the type of machine used, but generally here are 3 axes that move in X, Y, and Z directions. Some milling projects require movement along the 4th and 5th axes, which is becoming more and more popular for the most complex products.