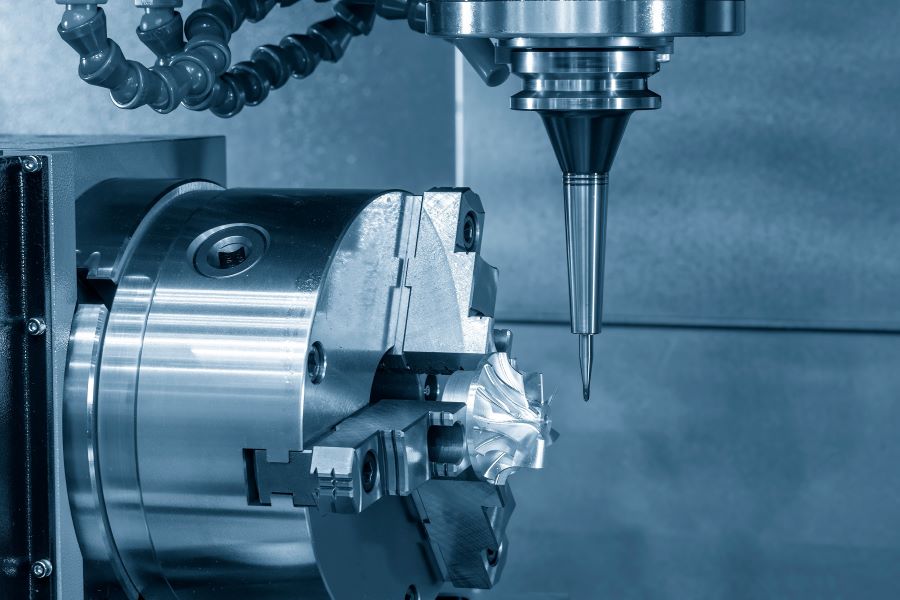

In the ever-evolving realm of CNC machining, the adoption of 5-axis technology has become a game-changer at Roberson Machine Company, pushing the boundaries of what was once thought possible. We believe that companies of any type can benefit from 5-axis machining – from those that excel in industries that need to create more basic parts, like consumer/commercial or packaging, to those that require some of the most intricately designed components, such as the aerospace or medical sectors.

Call us right away at 573-646-3996 or contact us online for a free quote. Our team has 20-plus years experience in utilizing our CNC machining and manufacturing solutions. We’d love to discuss your company’s next project or production run with you.

How Does 5-Axis CNC Machining Work?

Unlike more traditional 3-axis machining – which only moves sideways on the X-axis, vertically on the Y-axis, and back-and-forth on the Z-axis – 5-axis CNC machines can move along five different axes simultaneously. With the addition of the C-axis (table rotation) and the A-axis (table tilting), we now have an unprecedented freedom for intricate detailing and precise geometries that were once challenging or impossible.

Using a 5-axis CNC machine lets us approach a workpiece from all directions in a single operation, eliminating the need to manually reposition the workpiece between operations. Give us a call now at 573-646-3996 or reach out to us online for your free 5-axis machining quote.

Beyond Boundaries: Unveiling the Advantages of 5-Axis CNC Machining

Here we’ll explore the myriad advantages of 5-axis CNC machining, shedding light on how this innovative approach is revolutionizing our industry and making your next project quicker and more cost-effective:

- Create Complex Designs

- Shorter Lead Times

- Drilling – Using a traditional 3-axis machine for drilling a series of holes with compound angles, we would need a different setup for each hole drilled. This would be extremely time-consuming and costly. With our 5-axis machines though, we can orient the correct axis for each hole and let it rip.

- Material Removal – The cutting tool remains perpendicular to the cutting surface on our 5-axis machines, allowing for much faster removal of material. Doing it in different phases using the traditional method increases cycle times overall and the costs associated with those.

- Improved Surface Finish

- Flexibility in Material Handling

- Highly Accurate and Affordable Parts

- Extended Tool Life

This is one of the biggest reasons for the growth in 5-axis machining. Your part designers can explore more intricate and innovative designs, knowing that our 5-axis CNC machining can efficiently bring these complex shapes and contours to life. The boosted range of motion and positioning of the cutting tool provide an accuracy that eliminates the need for multiple tools or machines in our shop.

With 5-axis CNC machining, we can work on different surfaces of a workpiece at the same time. The reduced need for multiple setups and increased efficiency contribute to shorter lead times for your company’s production runs. A couple of examples are:

With 5-axis CNC machining, the last two axes help you maintain continuous contact between the cutting tool and the workpiece. This allows you to use a shorter cutting tool, which also transitions into the next benefit, resulting in a smoother surface finish and reducing the need for additional finishing processes or value added services. Your budget already thanks you. Call us at 573-646-3996 or connect with us online for your free quote.

Our 5-axis CNC machining services give us the ability to tilt and rotate the workpiece in one swoop, facilitating machining on multiple surfaces without the need for stopping and repositioning. This key feature is especially important for manufacturing intricate components.

The precision of 5-axis CNC machining is unrivaled and it reduces machining time, errors, and tool costs, ensuring consistent and accurate results across production runs. Our 5-axis machining solutions also eliminate the need for additional operations like fixturing and repositioning, resulting in cost savings for your project.

When lowering and orienting the shorter cutting tool, we reach higher cutting speeds without putting excessive pressure on the cutter. 5-axis machines can also approach the workpiece from various angles, allowing for optimal tool engagement. This reduces wear and tear and breakage, extending the life of our equipment. We pass these savings along to you.

The Advantages of 5-Axis CNC Machining at Roberson Machine Company

Embracing the advantages of 5-axis CNC machining opens up a world of possibilities for your company and its part designers. Partnering with Roberson Machine Company is the game-changer. We love to push the boundaries of what can be achieved, and our 5-axis machining allows us to do just that – reaching previously unforeseen geometric intricacies and increased efficiency.

Call us as soon as possible at 573-646-3996 or contact us online for your free quote.