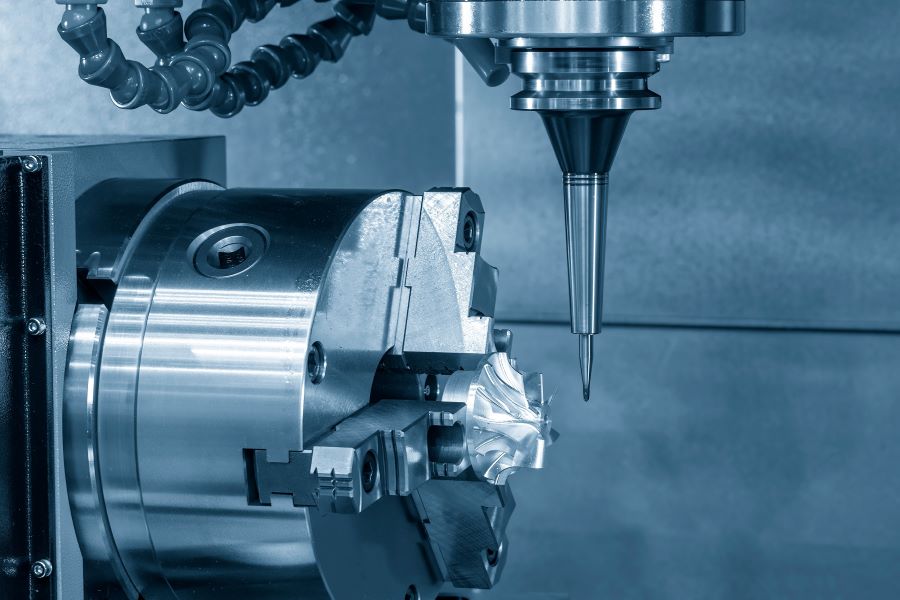

5 Axis CNC Machine Raleigh, NC. As industries in the Raleigh, NC area and throughout the country continue to evolve and expand, the demand for advanced machining solutions has led to the development and widespread use of 5-axis CNC machines at Roberson Machine Company. These machines epitomize the zenith of machining technology in our shop, providing unparalleled flexibility and precision for your Raleigh, NC company’s intricate components.

By cutting along five different axes, it’s possible to manufacture intricate components that meet your company’s exact specifications in Raleigh, NC with absolute precision – each and every time. Call the 5 axis CNC machine experts at Roberson Machine right away at 573-646-3996 or reach out to us online to get a quote on your next Raleigh, NC parts project.

5 Axis CNC Machine: Enhancing Your Raleigh, NC Company’s Part Production With Roberson Machine Company

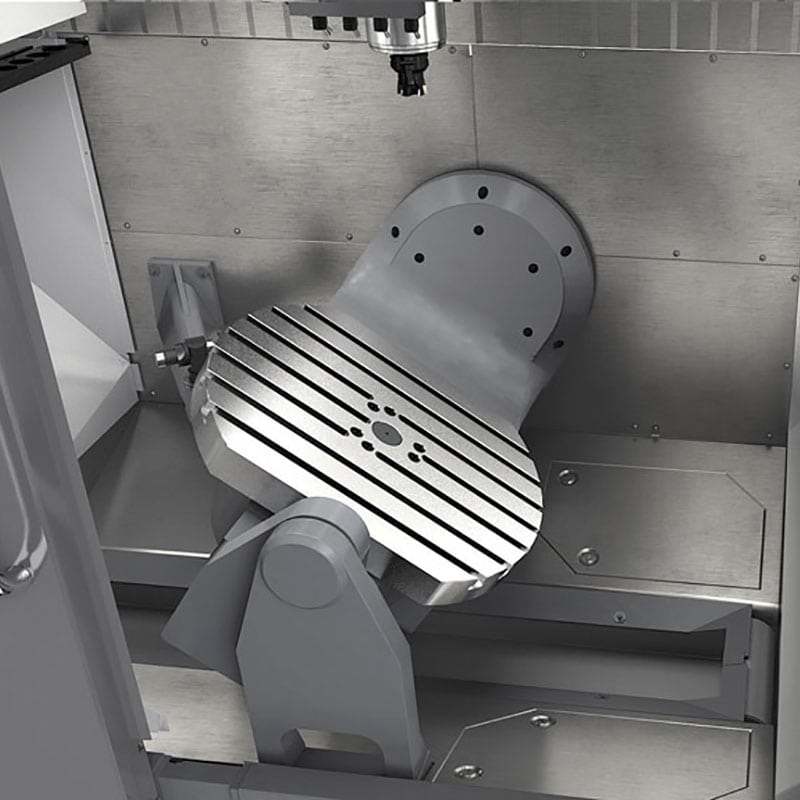

A 5-Axis CNC machine is a state-of-the-art device that can move a cutting tool or part along five different axes at the same time. At Roberson Machine Company, we have integrated these machines into many larger production runs due to their unrivaled precision. Beyond linear movements along the X (left-right), Y (forward-backward), and Z (up-down) axes, the tool or table of a 5-axis CNC machine can rotate along the A (rotating around the X axis) and B (rotating along the Y axis) axes.

This expanded range of movement allows for complex and precise machining from various angles, minimizing the need for numerous setups and greatly enhancing production efficiency and the accuracy of your Raleigh, NC parts.

5 Axis CNC Machine: What are the Benefits to Your Raleigh, NC Company?

A 5 axis CNC machine provides several benefits for manufacturing your Raleigh, NC company’s parts. Our machinists have more than 20 years of experience observing the growth of our machining solutions and the capabilities of our 5 axis CNC machines. Give our expert team a call now at 573-646-3996 or reach out to us online to help your company in Raleigh, NC get more information on the importance of using 5 axis CNC machines for your components and to get a free quote.

The following are some of the key benefits of choosing Roberson Machine Company’s 5 axis CNC machine solutions:

- Enhanced Design Flexibility for Your Raleigh, NC Company’s Components:

We can manufacture more innovative and complex parts that were previously difficult if not impossible to machine using 3-axis services. With the ability to move the tool, table, or part along five axes, there’s less need for complex fixtures, simplifying the production process on our end and reducing costs on your end. This flexibility is especially beneficial in sectors like aerospace, automotive, and medical, where precision and complexity are essential. - Increased Precision:

Our 5-axis machines can machine complex shapes in a single setup, reducing the potential for errors that can happen in scenarios with multiple setups. This capability ensures that your final component meets precise specifications and tighter tolerances by allowing machining from multiple angles without repositioning. - Better Surface Finish on Your Raleigh, NC Company’s Components:

By approaching the workpiece from various angles, our 5-axis CNC machine minimizes the need for repositioning or manual finishing and polishing, resulting in a smoother surface finish and better overall part quality. - Heightened Efficiency & Productivity:

The ability to move along multiple axes simultaneously allows for faster and more efficient material removal from the workpiece, regardless of the material type. This reduces production cycles and lead times, making 5 axis CNC machines an excellent choice for high-demand production environments.

5 Axis CNC Machine: Common Uses in and Around Raleigh, NC

The versatility and precision of the 5 axis CNC machines at Roberson Machine Company make them the go-to choice in a wide range of industries throughout Raleigh, NC and elsewhere. Some typical applications include:

- Medical Devices: We’ve had the privilege of machining accurate and complex parts for the medical industry. Recent projects include medical brace parts, acrylic/plastic medical parts, parts for a medical chair, and a medical valve body.

- Automotive: Some of the recent parts we have machined for automotive sector customers include crankshaft spacers and end of arm robot tooling used extensively in automotive component manufacturing.

- Aerospace: Roberson Machine Company leverages 5-axis CNC machines to produce complex aerospace industry components with intricate geometries and tight tolerances. We recently completed a customer’s production run for a roller for a lift system.

- Consumer Goods: Whether it’s an ink roller or a part that drives the shaft of a tape dispenser, we have recently machined several components for customers in the consumer and commercial goods industry.

Regardless of your industry in Raleigh, NC, call our team right now at 573-646-3996 or contact us online to talk about CNC machining solutions for your next project and to get a free quote.

What are the Differences Between a 3 Axis and a 5 Axis CNC Machine? Which One Works Best for Your Company’s Components in Raleigh, NC?

As noted, while the 5-axis CNC machine offers linear movement along the X, Y, and Z axes, along with rotational movement on the A and B axes, the 3-axis CNC machine is limited to linear movement only along the X, Y, and Z directions.

Some of the key differences between the two machines include:

Component Complexity

- 3 Axis: Best for simpler parts in Raleigh, NC with straightforward geometries and minimal complexity.

- 5 Axis: Essential for your Raleigh, NC company’s more complex components with intricate features and angles.

Machining Efficiency

- 3 Axis: Typically requires multiple setups to achieve intricate designs, which can extend production timelines.

- 5 Axis: Capable of producing complex parts for your Raleigh, NC company in a single setup, significantly cutting down production time.

Flexibility

- 3 Axis: Provides limited capability for handling complex part geometries and diverse angles in Raleigh, NC.

- 5 Axis: Provides exceptional flexibility, enabling machining from nearly any angle and accommodating a wider range of part geometries.

Ultimately, the choice between a 3-axis and a 5-axis CNC machine will depend on the complexity of the parts you require and your Raleigh, NC company’s budget considerations. Give the Raleigh, NC CNC machine experts at Roberson Machine Company a call right away at 573-646-3996 or reach out to us online for a quote.

Roberson Machine Company is a premier 5-axis CNC machine solutions provider for companies in Raleigh, NC and across the country. Also, our team of experts offers the following to clients throughout the Raleigh, NC area and nationwide:

- Manufacturing Oil & Gas Industry Parts

- Aluminum Aerospace Machining

- Medical Parts Manufacturer

- CNC Milling Aluminum

- Plastic Parts Manufacturer

- Precision Manufacturing

- Aerospace Machining

- Machined Plastic Parts

- CNC Companies

<img src="https://robersontool.com/wp-content/uploads/2024/07/5-Axis-CNC-Machine-at-Roberson-Machine-Company-2-768×1024.jpg" alt="5 Axis CNC Machine Raleigh, NC . Our experienced team can deliver higher quality products, reduce production times, and help your Raleigh, NC business stay ahead of the competition.

Maximize the potential of your Raleigh, NC parts and products with the 5-axis CNC machines at Roberson Machine Company. Call us as soon as possible for a free quote at 573-646-3996 or reach out to us online.