CNC machining is a popular manufacturing process for creating plastic parts and products at Roberson Machine Company. We utilize the method for customers’ projects that call for uniform and precise components with incredibly tight tolerances, no matter the size of the production run.

Call us right away at 573-646-3996 or contact us online to get a quote for your company’s next plastic CNC machining project. With over 20 years of experience, our skilled machinists know exactly the solution to use for your parts that will be competitively priced, have unparalleled accuracy, and fall within the best turnaround time for your team.

What Are the Best Plastics For CNC Machining at Roberson Machine Company?

We have the capacity to make many different plastic components using CNC machining in our machine shop. Some examples of possible industrial applications are:

- Parts for medical devices, such as housings for diagnostic equipment or components for prosthetics

- Automotive parts, like dashboard panels, interior trim pieces, and custom car parts

- Components for the aerospace industry, such as interior parts, instrument panels, and custom fittings

- Food and beverage components, like spray bars and kitchen line pieces

- Parts for various consumer and commercial goods, including kitchen appliances, home decor, and sporting equipment

- Virtually every other industry, like toys and board games, musical instruments, architectural, and much more

How Are Plastics Machined at Roberson Machine Company?

There are a number of choices when it comes to picking which plastic to use on your company’s next project. Many are easily machinable and are ideal for applications that require weight, transparency, corrosion resistance, and less friction. Give our skilled machinists a call at 573-646-3996 or contact us online for more information on the types of plastics to choose from.

We use the following CNC machining methods for manufacturing plastic parts:

CNC Turning For Plastics

CNC turning, a machining process at Roberson Machine Company that typically involves rotating a workpiece while our lathe’s cutting tool removes material to create a part’s shape, is frequently used on a variety of plastics, including:

- Delrin (Polyoxymethylene, POM): Probably the most machined of all CNC plastics, we suggest POM to customers who need a high-strength plastic with superior resistance to wear, weather, fuel, and chemical. The lone downside to this plastic is that it has poor resistance to acidic elements. Common uses include seat belt components and electronic cigarettes.

- Polypropylene (PP): Commonly used in CNC turning for producing components such as caps, connectors, and fittings, this plastic is cost–effective, versatile, and chemically resistant.

- Polytetrafluoroethylene (PTFE): Commonly known as Teflon, PTFE is valuable to customers looking for commercial products or parts. It’s most frequently found in the coating of a non-stick pan, but is also used for gaskets and electronic parts.

- Polyvinyl Chloride (PVC): Typically used for machining pipe fittings and electrical connectors, PVC is ideal for industrial applications where corrosion resistance and insulation are necessary.

- Polyetheretherketone (PEEK): Known for its resistance to liquids, chemicals, fatigue, wear, and temperatures up to 480°, PEEK is often suggested to customers as a replacement to metal. Examples of uses include airplane parts, dental syringes, and piston parts for car engines.

Call Roberson Machine Company today at 573-646-3996 or contact us online to get a free quote for your plastics CNC machining project.

CNC Milling For Plastics

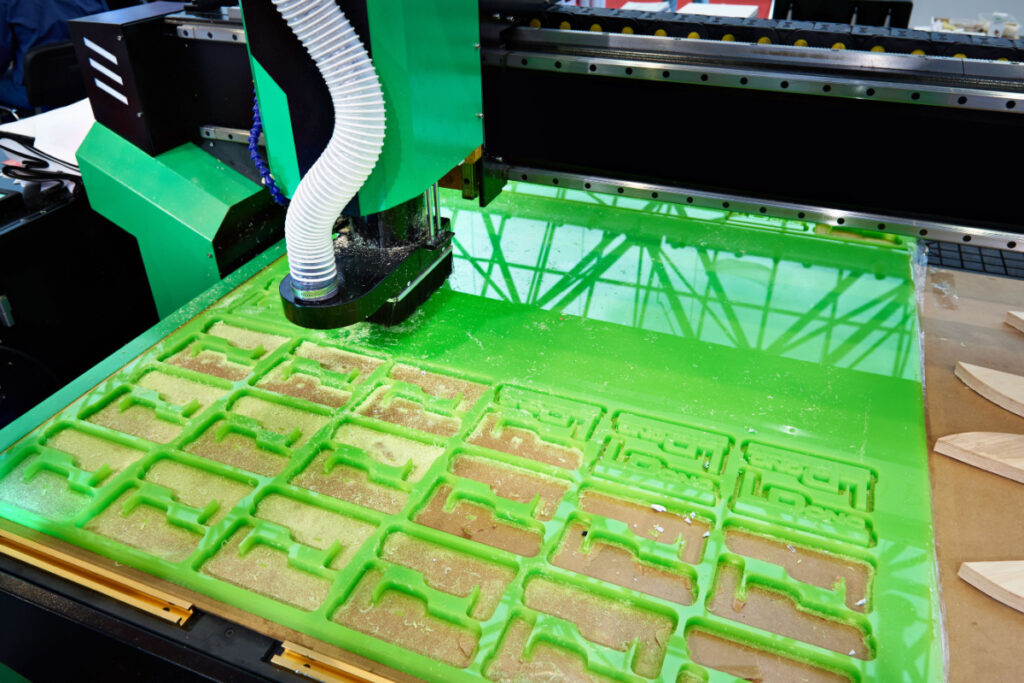

CNC milling is a machining process that uses a rotating tool or cutter to remove material from a solid piece to get a finished part. We use many different milling methods – including our 5 axis and multi axis machining – to achieve plastic parts with complicated geometries. Here are some common plastics we machine using our CNC milling services:

- Acrylic (PMMA): A rigid thermoplastic known for its optical clarity, acrylic is suitable for uses where transparency is important, such as signage, display cases, solar panels, and lenses.

- Acrylonitrile Butadiene Styrene (ABS): A versatile engineering thermoplastic known for its impact resistance, strength, and toughness. Common applications include functional prototypes, dashboard parts in cars, and consumer goods.

- Nylon (Polyamide, PA): Nylon is strong, durable, and resistant to abrasion. Common applications include gears, bushings, bearings, and even structural components.

- Polyethylene (PE): A lightweight and chemically resistant plastic, PE is typically used for applications involving food contact, outdoor products, and medical devices.

What Are the Best Plastics For CNC Machining? | Find Out By Contacting Roberson Machine Company Today

It’s important to note that the choice of plastic material for your company’s next job should take into account the specific requirements of your project – including cost, mechanical properties, temperature resistance, and chemical composition and compatibility. As always, the pros at Roberson Machine Company can help.

Give us a call today at 573-646-3996 or contact us online.