There is no question that accuracy and precision are essential in any manufacturing process at Roberson Machine Company. Every step must be precise, from machine programming to the actual parts machining. We would likely be out of business fairly quickly if we didn’t rely on being accurate and precise. However, there are several factors that need to be considered in CNC milling, such as speed, efficiency, and cost. It is important to strike a balance between all of these factors in order to produce the best possible results.

Call us today at 573-646-3996 or contact us online.

CNC Milling at Roberson Machine Company

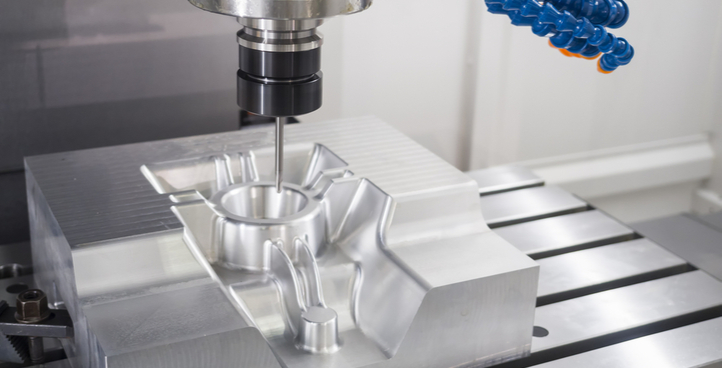

Like all of our CNC machining processes, CNC milling relies on computers to control the movement of tools. The level of precision and accuracy in CNC machining is controlled by CAD and CAM software creating G-code settings that direct tool movement. To achieve the best results for our clients in every industry, we focus on the following in our CNC milling services:

- Use of Quality Tools

- Upgrade the Machine Tool Promptly

- Understand the Material Properties

- Metals

- Aluminums:

- Stainless steel:

Although tool movements in CNC milling are automated, quality tools also add value to it. We regularly calibrate our CNC machines to ensure they are operated with the highest degree of precision.

CNC machine manufacturers add new features and regularly update their firmware and trends to improve productivity. Roberson Machine Company is always updating our machinery to stay ahead of the competition and stave off part deformities or machining errors.

Give us a call today at 573-646-3996 or contact us online. We use top-of-the-line materials for milling, including:

- Plastics:

- Tool Wear From Certain Materials

Our specialists understand these materials’ properties such as tensile strength, yield strength, thermal expansion, and Young’s modulus. A low yield strength material would likely deform more than a high yield strength material when subjected to the same cutting force.

Tool wear results from the abrasive contact between the tool and the workpiece. It causes a decrease in the size of the tooltip and a change in the shape of the tool cutting edge. This can cause the tool to cut inaccurately and produce poor-quality parts. Hard materials like steel can be machined with greater precision and accuracy than softer materials like aluminum. Our specialists keep an eye out to maintain the consistent cutting abilities of all of our machines.

How Do You Ensure Accuracy and Precision in CNC Milling? | Roberson Machine Company

Roberson Machine Company leads the way in CNC milling. We have over 20 years of experience in custom CNC services, are centrally located on our own land and in our own facilities, and strive to keep you coming back. We are your answer for on-demand, single-source manufacturing.

For the highest in accuracy and precision in CNC milling, call us today at 573-646-3996 or contact us online.